TruBattery

The Starter Battery Analyser

OVERVIEW

Developed on the back of 25 years of experience in battery monitoring, TruBattery, the automated starter battery analyser provides the most accurate tool for measuring battery life.

Batteries (and associated parts) are the most common failure mechanism causing emergency generators failing to start. Traditional manual methods do not provide the accuracy required.

TruBattery provides a safe and accurate method to testing batteries, minimising the risk of undetected battery failure.

FEATURES

Ease of Use

The system can be configured to send SMS message alerts or connect to any existing BMS or SCADA system.

The unit is designed to be easily installed: it remains compatible with new or old units.

Once installed, the unit is entirely self-contained: nothing needs to be attached or disconnected to perform the tests.

Safety

The patent-pending ‘Dual Lock’ contactor system ensures there is no possibility of the tester harming the battery.

Any unusual current or voltage readings terminates the test and produces an alarm.

Operators no longer need to access high current areas to perform tests.

Monitoring

Temperature, battery voltage and battery current are continously monitored, giving up-to-date readings.

Battery health is calculated using mathematical models and the values logged.

Failures are flagged and the user will recieve a notification that the battery requires their attention.

HOW IT WORKS

Manual tests can only tell you so much about a battery’s condition. Faults can be detected by a skilled mechanic but tests can be expensive and lengthy. Additionally, the lifespan of a battery can not be projected.

Using TruBattery, multiple tests are performed to ensure accurate battery health readings and to predict when your battery will fail. Find out what tests we use to measure your battery health.

-

A Pass/Fail test based on the voltage reading of a fully charged battery

-

To pass, the voltage must stay above 9.6V/19.2v (on 12/24v battery) at 10°C (50°F) and higher

-

The impact of colder temperatures is accounted for

Automated Cold Crank Amps

-

A non-invasive method is used to measure the resistance under load

-

Two discharge loads of different currents and duration are applied

-

The voltage signatures are evaluated under the loads and readings calculated

Two-tier DC Load

-

The profile of the discharge is recorded and plotted over time

-

The logged results are used to project the life of the battery

-

Significant deterioration in the tests is also recorded as a failure

State of Health

TECHNICAL DETAILS

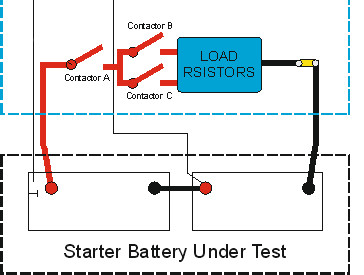

Dual Lock System

The Microwatt ‘Dual Interlock’ ensures there is no possibility of the tester harming the battery.

The system works by ensuring that contactor ‘A’ never opens under load, under normal conditions.

This ensures that arcing cannot cause a fault & that the contactors are functioning correctly before a test can proceed.

Battery State of Health Model

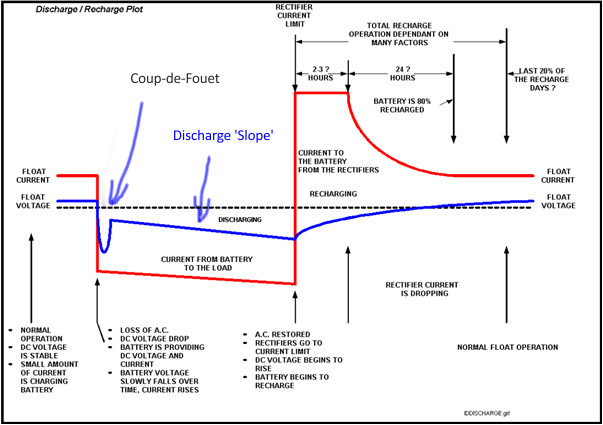

We combine two mathematical models to analyse the performance of the starter battery.

1. We have extended our 6th order polynomial model which analyses the discharge curve AFTER the rise . The slope at this point tells us the battery capacity.

2. We monitor the depth of drop of the Coup de fouet when under load – temperature compensated.

3. We use Peukwerts modelling if CATE is monitoring the charge current (option)

(expresses the capacity of a battery in terms of the rate at which it is discharged. As the rate increases, the battery’s available capacity decreases)

4. We log all results and predict ‘State of Health’ from the combined models.